The vinyl resurgence continues to shape the music industry landscape, with production facilities worldwide adapting to increasingly knowledgeable consumers. This comprehensive overview examines how enhanced consumer understanding of vinyl manufacturing processes influences market dynamics and production standards.

Current Market – An Overview

The vinyl market has maintained its upward trajectory, with the British Phonographic Industry reporting a 17% increase in sales volume compared to the previous year. This growth isn’t merely about nostalgia—today’s vinyl consumers demonstrate unprecedented technical knowledge about pressing quality and manufacturing processes.

Consumer Technical Awareness

Modern vinyl enthusiasts regularly discuss technical specifications that were once primarily industry concerns. Popular discussion points on platforms like Discogs and Reddit’s r/vinyl include:

Manufacturing specifications:

- 140g vs 180g pressing weights and their acoustic implications

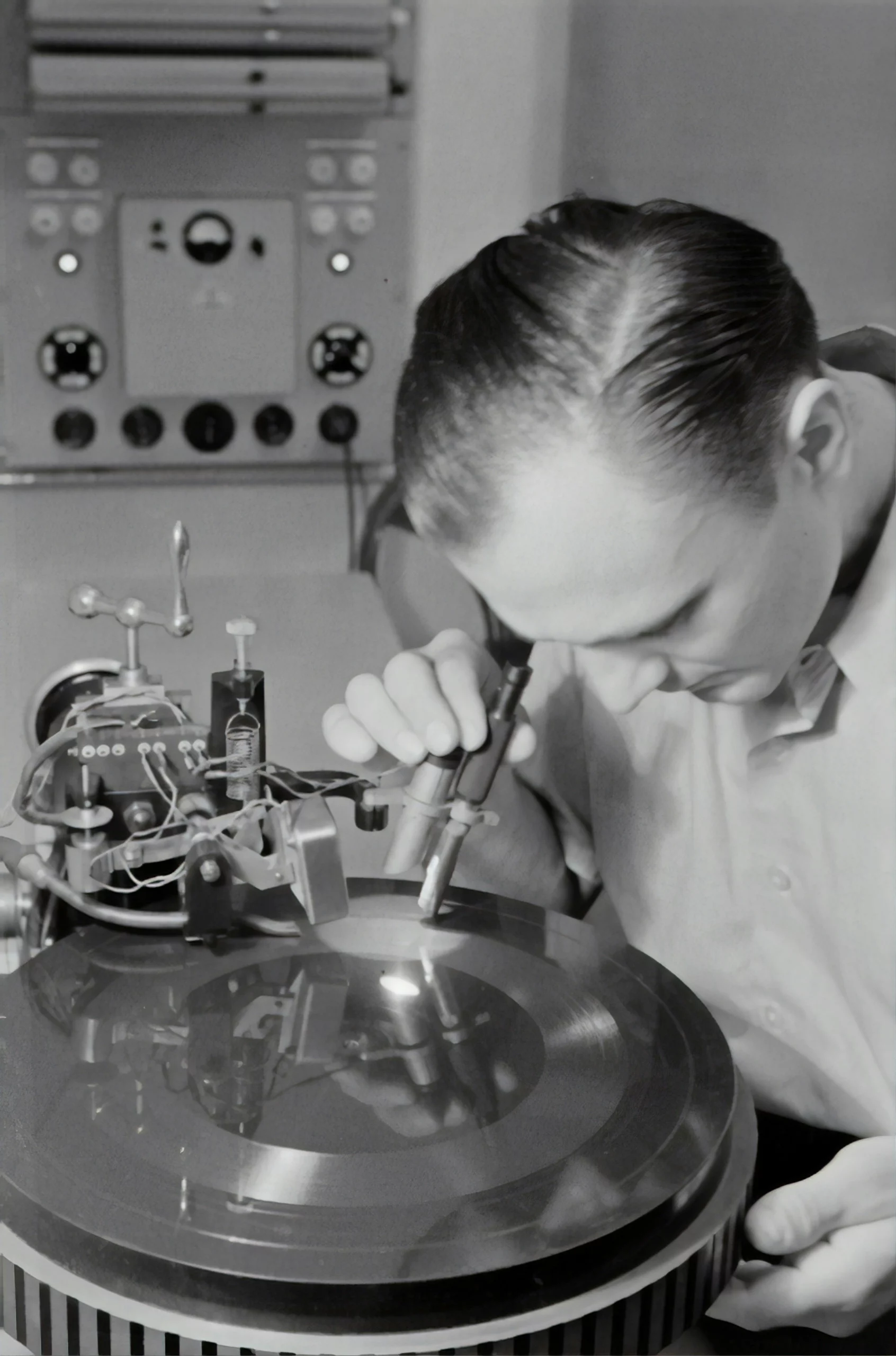

- Differences between Direct Metal Mastering (DMM) and lacquer cutting

- Impact of colour variants on sound reproduction

- Quality variations between pressing facilities

These discussions directly influence purchasing decisions, with Discogs marketplace data showing price premiums of 15-30% for pressings from renowned facilities.

Production Standards and Wait Times

Current industry standard wait times for vinyl production average 20-24 weeks at major pressing plants, reflecting both high demand and meticulous quality control processes. This timeline typically includes:

Processing stage durations:

- Test pressing and approval: 2-3 weeks

- Production queue: 14-16 weeks

- Quality control and packaging: 4-5 weeks

Geographic Manufacturing Trends

Different regions have developed distinct reputations for vinyl manufacturing:

German pressing facilities remain highly regarded for consistent quality control, particularly in dance music production. Japanese pressing plants continue their tradition of exceptional attention to detail, especially notable in their high-quality heavyweight pressings. British plants have seen significant technological upgrades, particularly in automated quality control systems.

Technical Specifications Driving Consumer Choice

Recent marketplace data reveals specific technical aspects that influence consumer decisions:

Pressing weights:

- Standard 140g pressings maintain popularity for cost-effectiveness

- 180g pressings command premium prices for perceived audio benefits

- Ultra-heavyweight 200g pressings occupy a niche audiophile market

Mastering methods:

- Traditional lacquer cutting remains preferred for its warm characteristics

- DMM gains traction for its consistency and detail reproduction

- Half-speed mastering continues to command premium prices

Quality Control Evolution

Modern pressing plants have implemented advanced quality control measures responding to consumer awareness:

- Automated inspection systems now check for:

- Vinyl compound purity

- Surface noise levels

- Groove depth consistency

- Label alignment precision

Market Data Insights

Discogs marketplace statistics reveal telling patterns about consumer preferences:

- Original pressings from renowned facilities maintain 20-25% higher resale values

- Coloured vinyl variants show 10-15% higher initial sales figures

- Heavy-weight pressings consistently command 15-20% price premiums

- Quality control documentation increases resale value by 5-10%

Production Challenges and Solutions

Contemporary pressing plants face several challenges in meeting consumer expectations:

Primary challenges include:

- Raw material quality consistency

- Production capacity limitations

- Technical staff expertise requirements

- Quality control maintenance at scale

Industry solutions have emerged through:

- Advanced automated monitoring systems

- Standardised quality control protocols

- Enhanced staff training programmes

- International quality standards implementation

Future Outlook

The vinyl manufacturing sector continues evolving with consumer knowledge. Pressing plants increasingly embrace transparency about their processes, recognising that informed consumers make decisions based on technical merit rather than merely artist popularity or release scarcity.

Key trends likely to influence future development include:

- Enhanced quality control automation

- Greater production process transparency

- Increased focus on consistent pressing weights

- Continued investment in technical expertise

This evolving landscape demonstrates how consumer technical knowledge shapes production standards and market dynamics in the vinyl industry. As enthusiasts continue to deepen their understanding of manufacturing processes, the industry responds with enhanced quality control and technical transparency, creating a more sophisticated market for all participants.

Leave a Reply